Blog

Wyzenbeek Abrasion Resistance Test

Wyzenbeek Abrasion Resistance Test Professional Guide

——Comprehensive Analysis of U.S. Furniture Industry Standards

1. Test Principle

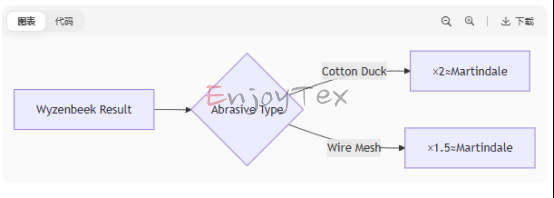

The Wyzenbeek test employs reciprocating friction using standard 10 cotton duck or wire mesh as abrasives. A dual friction head performs linear abrasion on specimens to simulate long-term furniture use scenarios.

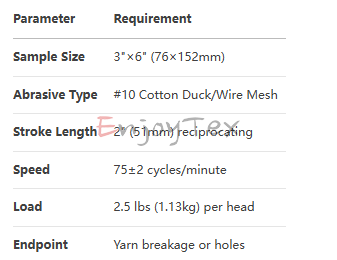

2. Core Test Parameters

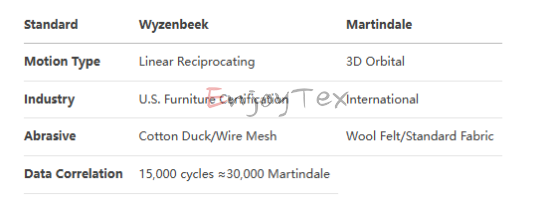

3. Test Standard Comparison

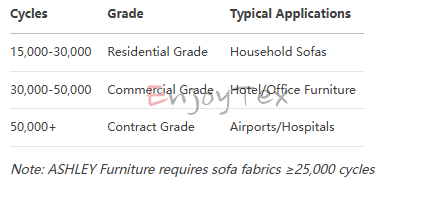

4. Wear Resistance Classification

5. Key Influencing Factors

(1) Abrasive Selection

- Cotton Duck: Simulates clothing friction (results 20-30% higher than wire mesh)

- Wire Mesh: Evaluates extreme wear (ASTM D4157 compliant)

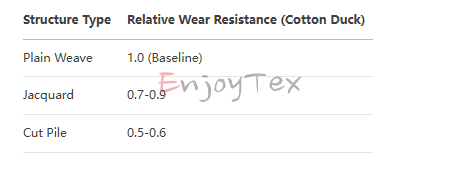

(2) Fabric Structure Impact

6. Test Protocol

1. Sample Preparation:

- Condition 24 hours (21±1°C, 65±2% RH)

- Avoid sampling within 10cm of fabric edges

2. Equipment Calibration:

- Monthly pressure check (2.5±0.1 lbs)

- Replace cotton duck every 5,000 cycles

3. Data Recording:

- Inspect every 5,000 cycles

- Document wear patterns (macro/micro photos)

7. Industry Applications

- Herman Miller Office Chairs:

- Requirement: 50,000 cycles (wire mesh)

- Material: 100% ripstop nylon

- La-Z-Boy Recliners:

- Requirement: 30,000 cycles (cotton duck)

- Treatment: Nano stain-resistant coating

8. Martindale Conversion Reference

Example: 30,000 Wyzenbeek (cotton duck) ≈60,000 Martindale

9. Latest Developments

- Automated Testing:

Robotic sample handling (300% efficiency gain)

- Environmental Simulation:

Combined temperature/humidity cycling (23°C/50%RH→38°C/85%RH)

Note: ASTM D4157-23 update added synthetic abrasive options.

Testing Service Recommendations

1. Certified Labs:

- Intertek/SGS provide AATCC-certified reports

2. Equipment Selection:

- Basic: $15,000-$20,000 (James Heal)

- Advanced: $35,000+ (real-time monitoring)

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China