Blog

Martindale Abrasion Testing

Professional Guide to Martindale Abrasion Testing

——Comprehensive Analysis from Principles to Applications

1. Test Principle

The Martindale test simulates repeated friction in daily use through Lissajous motion trajectory (24.5±0.5mm),

causing multi-directional abrasion between the specimen and standard abrasive material to evaluate fabric wear resistance.

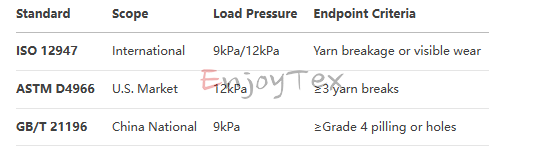

2. Testing Standard Comparison

3. Key Test Parameters

- Sample Preparation:

- Size: Diameter ≥140mm (effective friction area Ø38mm)

- Quantity: Minimum 3 parallel samples

- Preconditioning: GB/T 6529 standard environment (20±2°C, 65±4% RH) for 24h

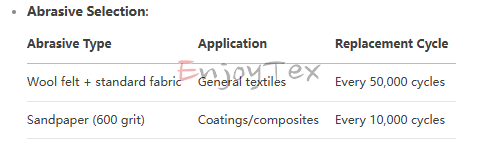

- Abrasive Selection:

- Motion Parameters:

- Speed: 47.5±2.5 rpm

- Trajectory: 3D spatial friction (X-Y-Z axis compound motion)

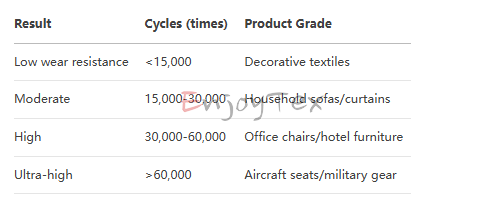

4. Data Interpretation & Grading

Note: Luxury car seats (e.g., Mercedes S-Class) require ≥100,000 cycles

5. In-Depth Influencing Factors

(1) Material Factors

- Fiber type:

`Nylon 6,6 (best) > Polyester > Cotton > Viscose`

- Yarn structure:

- Plied yarns show 40-60% higher abrasion resistance than singles

- Filament yarns outperform staple fibers

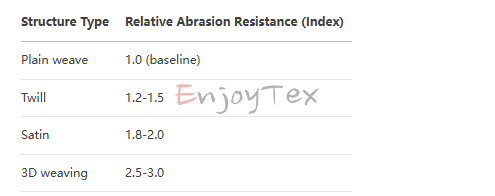

(2) Fabric Structure

(3) Finishing Processes

- Resin treatment: Improves wear resistance by 20-30%

- Nano-coatings (e.g., SiO₂): Reduce friction coefficient by 15-25%

6. Common Operational Issues

- Error Sources:

- Delayed abrasive replacement (recommended: inspect every 20,000 cycles)

- Over-tightened samples (should lie flat naturally)

- Non-standard temperature/humidity

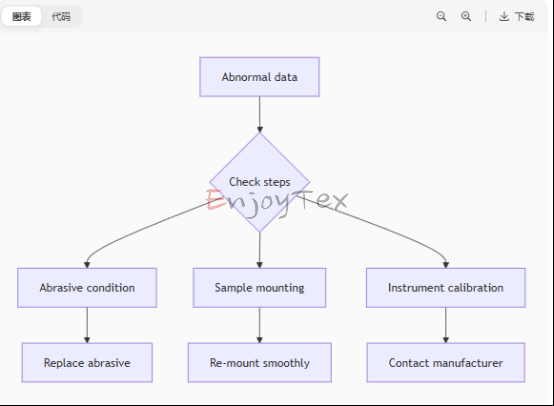

- Troubleshooting:

7. Industry Application Cases

- IKEA Sofa Fabric:

- Requirement: ≥25,000 cycles

- Material: 65% polyester + 35% cotton twill

- Tesla Model 3 Seats:

- Requirement: ≥50,000 cycles

- Treatment: Nano hydrophobic coating + stain resistance

- Military Tent Fabric:

- Requirement: ≥100,000 cycles

- Material: 500D nylon 66 + PU coating

8. Testing Service Selection

1. Certified Labs:

- SGS/ITS provide CNAS-accredited reports (~¥800-1,500/sample)

2. In-House Setup:

- Equipment cost: ¥50,000-120,000 (local/imported options)

3. Rapid Pre-Screening:

- 5,000-cycle preliminary test (70% cost reduction)

9. Latest Technological Trends

- Smart Testing Systems:

- Real-time friction coefficient monitoring (±3% deviation)

- AI visual endpoint detection (replaces manual observation)

- Accelerated Testing:

- 70°C + 15% RH (simulates 5 years of use)

Note: The 2023 ISO 12947-4 update added specifications for elastic fabrics.

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China