Blog

Fabric Abrasion Resistance Testing

Comprehensive Guide to Fabric Abrasion Resistance Testing

——From Basic Tests to Industry Applications

1. Key Testing Standards

Standard | Application | Principle | Industries |

Martindale | Furniture/Apparel Fabrics | Circular sample abrasion | Home Textiles/Auto Interiors |

Taber | Coated/Composite Materials | Rotating abrasive wheels | Footwear/Luggage |

Wyzenbeek | U.S. Furniture Certification | Cotton duck reciprocating friction | American Upholstery |

ISO 12947 | International Wear Resistance | Modified Martindale Method | EU Market Products |

2. Testing Method Comparison

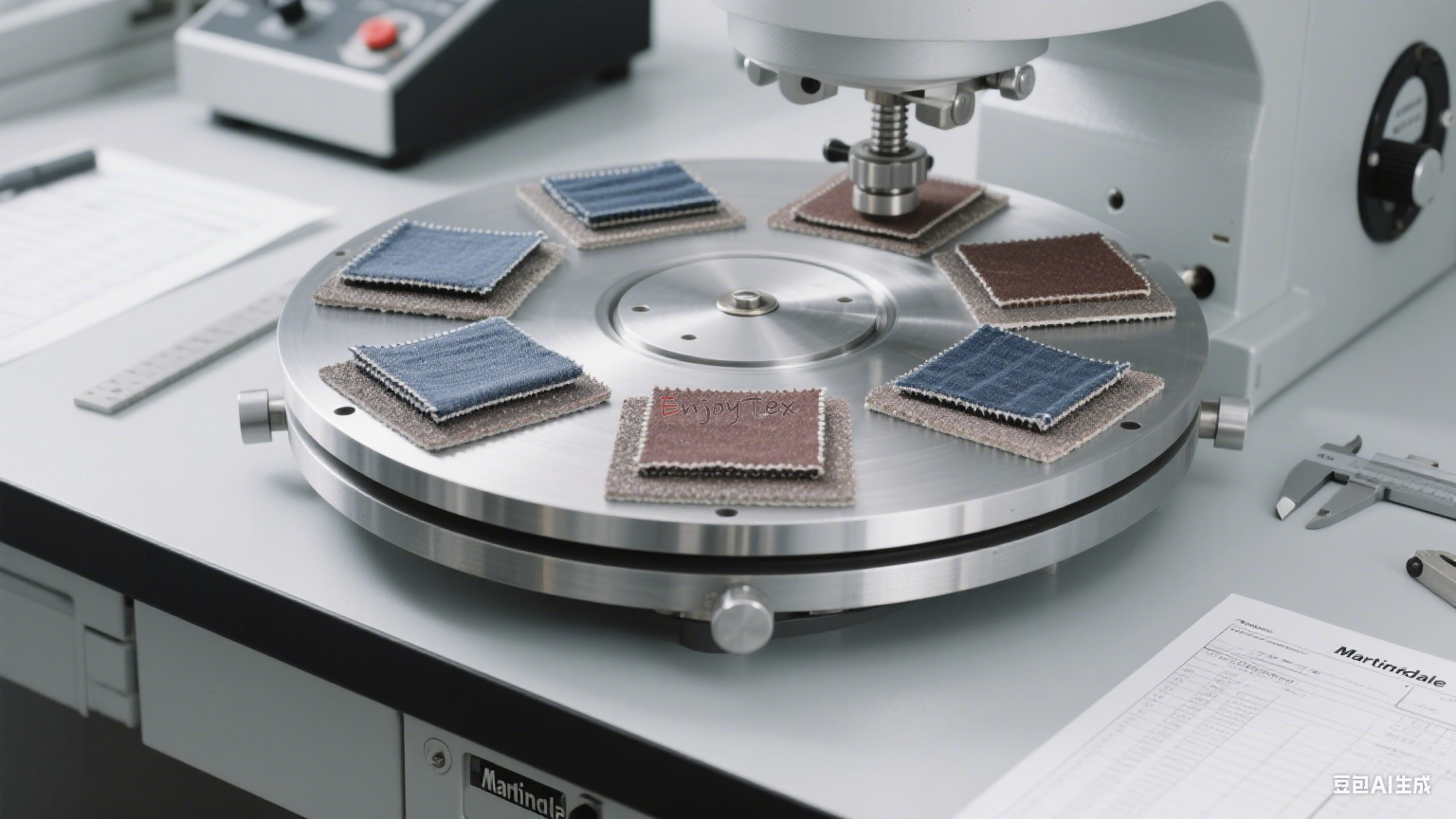

(1) Martindale Test

- Sample Size: Ø140mm

- Pressure: 9kPa/12kPa (furniture/apparel grade)

- Endpoint Criteria:

- ≥3 yarn breaks (ASTM D4966)

- ≥Grade 4 pilling (GB/T 4802.1)

(2) Taber Test

- Abrasive Wheels: H18 (coarse)/CS10 (fine)

- Load: 500g/1000g

- Data Recording: Weight loss (mg) per 500 cycles

(3) Practical Applications

3. Equipment & Operational Key Points

(1) Martindale Tester

- Critical Parameters:

- Motion Path: Lissajous curve (24.5±0.5mm)

- Speed: 47.5±2.5rpm

- Common Errors:

- Delayed abrasive replacement (change every 20,000 cycles)

- Insufficient sample preconditioning (per GB/T 6529)

(2) Taber 5135 Model

- Calibration Requirements:

- Wheel diameter wear <0.5mm

- Vacuum pressure maintained at 15-20kPa

4. Data Interpretation & Grading

5. Influencing Factors

(1) Material Properties

- Fiber Type: Nylon 66 > Polyester > Cotton

- Yarn Structure: Plied > Single

- Fabric Density: High > Low

(2) Finishing Processes

- Resin treatment improves abrasion resistance by 20-30%

- Nano-coatings (e.g., SiO₂) reduce friction coefficient

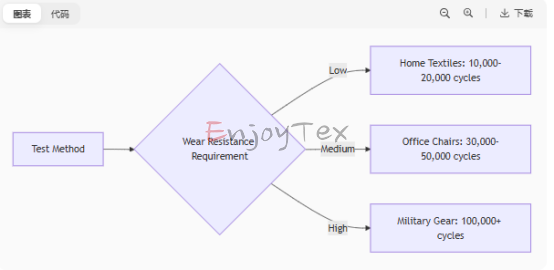

6. Industry-Specific Requirements

7. Technological Advancements

- Smart Wear Monitoring:

Embedded RFID chips record real-time friction cycles

- AI Visual Grading:

Machine vision auto-evaluates pilling/damage (<5% error)

- Accelerated Testing:

70°C + 85% RH environment simulates 5-year wear

Note: Tesla Cybertruck seat fabric requires 200,000 Martindale cycles, far exceeding industry norms.

Testing Service Selection Guide

1. Certified Labs:

- ITS/SGS provide CNAS-accredited reports

2. In-House Equipment:

- Entry-level Martindale tester: ~¥50,000-80,000

3. Cost Optimization:

- Preliminary screening (e.g., 5,000 cycles) before full testing

(Reference: GB/T 21196.1-2020 "Textiles - Determination of Abrasion Resistance by Martindale Method" is China's latest standard.)

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China