Blog

WOVEN FABRIC

Woven fabric refers to textiles formed by perpendicular interlacing of warp and weft yarns, characterized by stable structure and distinct texture.

It represents the most widely used fabric type (accounting for over 70% of global textile production).

1.Key Characteristics

Property | Advantages | Limitations |

Structural Stability | Resists deformation, good shape retention | Low elasticity (requires spandex blending) |

Strength

| High tear resistance and durability | Reduced breathability in heavy fabrics |

Design Versatility | Thousands of patterns achievable through weave variations | Complex jacquard patterns increase costs |

Production Efficiency

| Modern looms reach speeds up to 2000 RPM | Minimum order quantity typically ≥1000m |

2. Weave Structure Classification

(1) Basic Weaves

- Plain Weave: 1 up/1 down (e.g., poplin, canvas)

- Twill Weave: 2 up/1 down etc. (e.g., denim, khaki)

- Satin Weave: 4 up/1 down etc. (e.g., sateen, formalwear fabrics)

(2) Specialty Weaves

- Jacquard: Complex patterns requiring electronic jacquard looms

- Double Cloth: Different textures on each side

- Leno Weave: Slip-resistant structure (e.g., medical gauze)

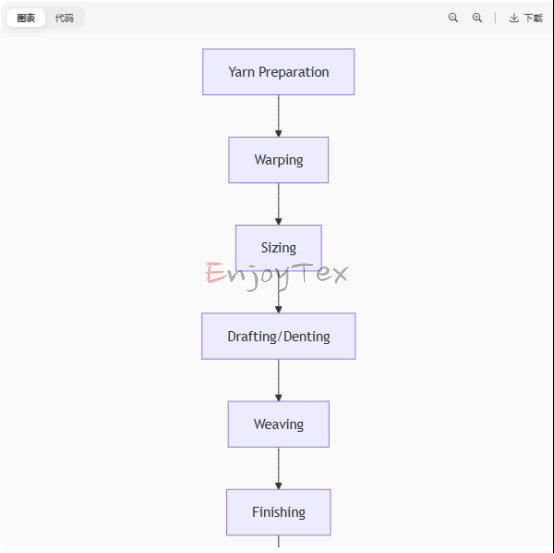

3. Manufacturing Process

Key Process Notes:

- Warping: Ensures uniform tension (±2% tolerance)

- Sizing: Enhances yarn strength (8-12% size pickup)

- Weaving: Rapier looms for small batches, air-jet looms for high efficiency

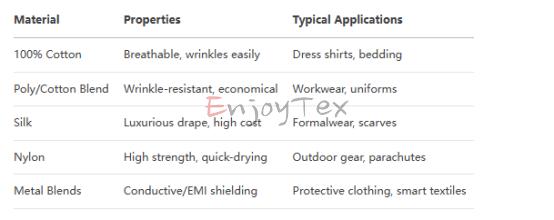

4. Common Materials & Applications

5. Technical Parameters

- Yarn Count & Density: e.g., 40×40/128×68 indicates warp 40s, weft 40s, warp density 128 ends/inch, weft density 68 picks/inch

- Weight Ranges:

- Lightweight: 80-120g/m² (summer shirts)

- Standard: 120-200g/m² (pants)

- Heavyweight: 200-400g/m² (outerwear/workwear)

6. Industry Innovations

- Smart Weaving: IoT-enabled looms for real-time defect detection (30% waste reduction)

- Eco-Technologies: Waterless dyeing (60% water savings)

- High Performance: Carbon fiber woven fabrics (5000MPa tensile strength)

7. Procurement Guidelines

(1). Define Purpose: Nylon for outdoor gear, cotton for home textiles

(2) Quality Checks:

- Colorfastness ≥4 (ISO 105-A02)

- Shrinkage ≤3% (AATCC 135)

(3) Supplier Evaluation:

- OEKO-TEX® certification

- MOQ policies

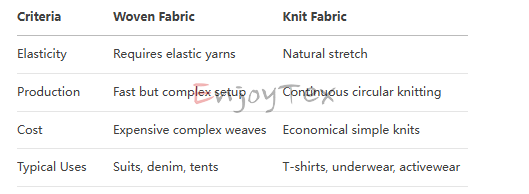

8. Comparison with Knit Fabrics

9. Quality Testing Methods

- Tear Strength: ASTM D1424 (Elmendorf)

- Abrasion Resistance: Martindale (ISO 12947)

- Color Difference: Spectrophotometer ΔE≤1.0

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- SUEDE FABRIC 2025-08-11

- LINEN FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China