Blog

Taber Abrasion Test

Taber Abrasion Test Professional Guide

——Comprehensive Analysis from Principles to Applications

1. Test Principle

The Taber test evaluates material wear resistance through rotating abrasive wheels under controlled load, simulating long-term surface wear in real-world applications.

Key Components:

- Abraser Unit: Dual abrasive wheels (typically H18 or CS10)

- Rotating Platform: Turns at 72±2 rpm

- Load Weights: Standard 500g or 1000g per wheel

2. Testing Standards Comparison

Standard | Application Scope | Wheel Type | Load (g) | Endpoint Criteria |

ASTM D4060 | General Coatings | CS10 | 1000

| Weight loss (mg) or visual wear |

ISO 9352 | Plastics | H22 | 500 | ΔHaze ≥10% |

GB/T 5478 | Chinese National Standard | H18 | 1000 | 1000-cycle mass loss (mg) |

3. Key Test Parameters

Sample Preparation:

- Size: 100×100mm (min) with center hole Ø6.5mm

- Thickness: 1-10mm (varies by material)

- Conditioning: 23±2°C, 50±5% RH for 24h

Abrasive Wheels:

Type | Grit | Suitable Materials | Lifetime (cycles) |

CS10 | Fine | Paints, soft plastics | 500-1000 |

H18 | Coarse | Hard coatings, metals | 300-500 |

H22 | Very Coarse | Rubber,textured surfaces | 200-300 |

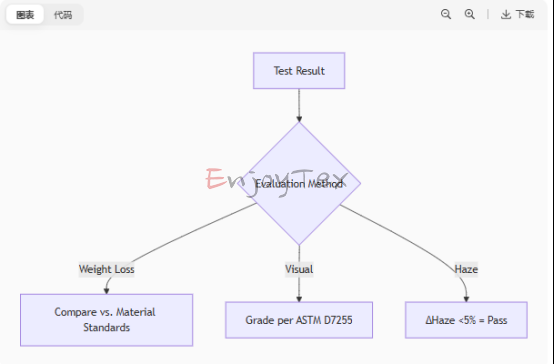

4. Wear Resistance Evaluation Methods

1. Weight Loss Method

- Measure sample mass pre/post-test (0.1mg precision)

- Calculate mass loss per 1000 cycles (mg/1000 cycles)

2. Visual Rating System

Grade | Description | Typical Applications |

1 | No visible wear | High-gloss surfaces |

3 | Slight abrasion marks | Automotive interiors |

5 | Base material exposed | Industrial flooring |

3. Haze Measurement (For transparent materials)

- Use spectrophotometer per ASTM D1003

5. Industry-Specific Requirements

Industry | Test Protocol | Acceptance Criteria |

Automotive | 1000 cycles, CS10, 500g | ≤50mg weight loss |

Flooring | 5000 cycles, H18, 1000g | Visual Grade ≤3 |

Consumer Electronics | 300 cycles, CS17, 250g | No coating penetration |

6. Factors Affecting Results

Material Factors:

- Hardness: Higher = Better resistance (e.g., Ceramic > Steel > PP)

- Surface Finish: Polished > Textured

Test Conditions:

- 10% variance from 72 rpm significantly alters results

- 50g load difference can double wear rate

Wheel Maintenance:

- Dress wheels every 50 cycles with aluminum oxide stone

- Replace when diameter reduces by 5%

7. Advanced Applications

1. Multi-Axis Testing

- Combine Taber with linear abrasion (e.g., Taber Linear Abraser)

2. In-Situ Monitoring

- Integrated sensors measure:

- Friction coefficient (μ)

- Surface temperature ΔT

3. Custom Environments

- Temperature-controlled chamber (-40°C to 200°C)

- Liquid immersion testing

8. Data Interpretation Guide

9. Equipment Selection

Model | Key Feature | Price Range (USD) |

Taber 5135 | Basic manual operation | $15,000-$20,000 |

Taber 5750 | Automated mass measurement | $35,000-$45,000 |

Taber 5900 | Multi-environment testing | $60,000+ |

Maintenance Tips:

- Monthly motor calibration

- Quarterly load cell verification

- Annual full system overhaul

10. Latest Developments (2024)

- AI-Assisted Grading: Computer vision for instant wear classification

- Eco-Friendly Wheels: Recycled abrasive materials with equal performance

- Blockchain Reporting: Tamper-proof test data recording

Note: New ISO 23150 (2024) introduces unified wear rate calculation methods.

Why Choose Taber Testing?

✅ Universal - Covers metals, plastics, coatings, textiles

✅ Precise - Quantitative data (mg loss) + qualitative (visual)

✅ Standardized - Accepted by global certification bodies

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China