Blog

Polypropylene (PP) Fiber Fabric

Polypropylene (PP) Fiber Fabric

——From Industrial Material to High-Performance Textile

1. Fundamental Definition

Polypropylene fiber (PP fiber) is a synthetic fiber polymerized from propylene (CH₂=CH-CH₃). As the only textile fiber that can float on water (density: 0.91g/cm³), its purely hydrocarbon molecular structure lacks polar groups. Global annual production reaches ~7 million tons (12% of synthetic fibers).

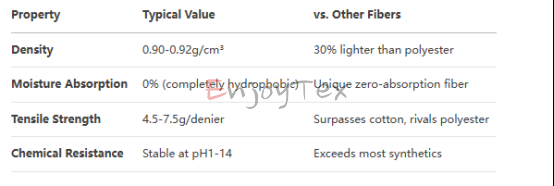

2. Core Performance Parameters

3. Key Production Technologies

(1) Melt Spinning Process

- Conventional: 160-170°C melting, 2000-3000m/min speed

- High-speed: ≥4000m/min (20% higher orientation)

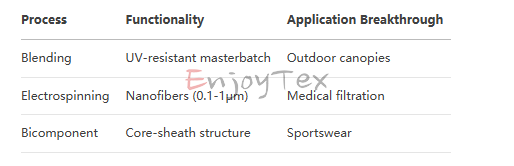

(2) Modification Technologies

4. Key Advantages

(1) Physical Properties

- Lightest fiber: 40% lighter than cotton at equal coverage

- High strength: Fishing nets use PP with 8g/d tenacity

- Chemical inertness: Resists strong acids/alkali (except HNO₃)

(2) Functional Features

- Moisture wicking: Capillary rise >15cm (ideal for quick-dry fabrics)

- Electrical insulation: Volume resistivity 10¹⁶Ω·cm (cable standard)

- Food-contact safe: FDA certified

(3) Economic Benefits

- Raw material cost: 20-30% cheaper than polyester

- Energy efficiency: Melts at just 165°C (vs. polyester's 260°C)

5. Critical Limitations

(1) Thermal Weakness

- Softening point: 140-150°C (iron below 100°C)

- Boiling water shrinkage: Up to 15%

(2) Degradation Issues

- UV sensitivity: Requires 2-5% UV stabilizers outdoors

- Oxidative degradation: ~8% annual strength loss at 50°C

(3) Processing Challenges

- Difficult dyeing: Requires dope dyeing/modification

- Poor adhesion: Needs plasma treatment for bonding

6. Modification Breakthroughs

(1) Heat Resistance

- Nano-SiO₂ modification: Heat deflection temp ↑to 120°C

- Cross-linking: Boiling water shrinkage ↓to <3%

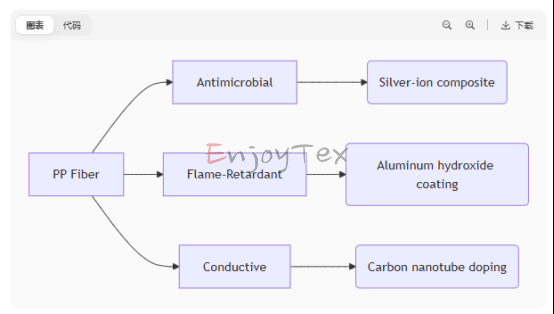

(2) Functionalization

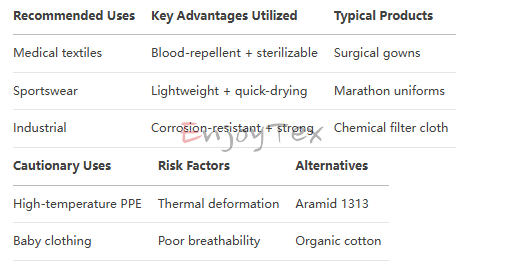

7. Application Guidelines

8. Market Data

- Cost Comparison:

- PP filament: ¥15-25/kg

- PET filament: ¥20-35/kg

- Lifespan:

- Outdoor gear: 3-5 years (with UV treatment)

9. Future Trends

- Bio-based PP:

Sugarcane-derived propylene (Braskem's commercial tech)

- Smart Response:

Fiber pores auto-expand >35°C (thermoregulation)

- Recycling Revolution:

99.9% pure chemical depolymerization (PureCycle tech)

Selection Tips:

- Outdoor use → Choose ≥3% UV-stabilized grades

- Medical → Verify ISO 10993 biocompatibility

- Performance sportswear → Opt for bicomponent wicking structures

(Note: Next-gen metallocene-catalyzed PP fibers are breaking traditional performance limits.)

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China