Blog

Acrylic Fiber Fabric

Acrylic Fiber Fabric

——From Synthetic Wool to Functional Fibers: A Scientific and Market Perspective

1. Fundamental Definition

Acrylic fiber (polyacrylonitrile fiber, PAN) is a synthetic fiber primarily composed of acrylonitrile monomer (CH₂=CH-CN, ≥85%). Its cyanide group (-C≡N) molecular structure grants it wool-like properties, with global annual production reaching ~3 million tons (15% of synthetic fiber market).

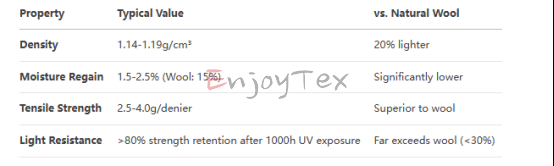

2. Core Performance Parameters

3. Key Production Technologies

(1) Polymerization Process

- Solution polymerization: DMF/DMSO solvent, >95% conversion rate

- Suspension polymerization: Cost-effective but broader molecular weight distribution

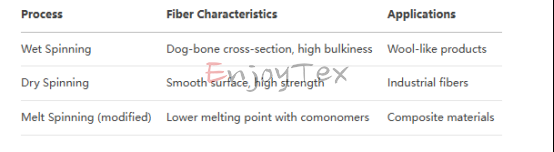

(2) Spinning Methods

4. Advantages Analysis

(1) Biomimetic Properties

- Thermal resistance: 0.051W/(m·K) (close to wool)

- Crimp: 3D helical crimp improves loftiness by 30%

(2) Durability

- Mold/microbe resistance: Grade 0 (GB/T 24346-2009)

- UV protection: UPF >50+ (ASTM D6544)

(3) Processing Benefits

- Dyeability: Colors at 100°C (wool requires boiling)

- Shape memory: Permanent form retention after heat-setting

5. Limitations

(1) Comfort Issues

- Static buildup: Resistivity 10¹²Ω·cm (requires anti-static treatment)

- Moisture management: Wicking height <5cm (Cotton: 12cm)

(2) Environmental Challenges

- Toxic monomer: Acrylonitrile (IARC Group 2 carcinogen)

- Slow degradation: >80 years for natural decomposition

(3) Usage Constraints

- Heat sensitivity: Softening point 190-240°C (avoid ironing)

- Synthetic feel: Glossy appearance in standard products

6. Modification Breakthroughs

(1) Functional Enhancements

- Anti-pilling: Reduced polymerization degree (DP <800)

- Flame-retardant: Vinyl chloride comonomer (LOI >28%)

- Microfiber: <0.8dtex cashmere-like texture

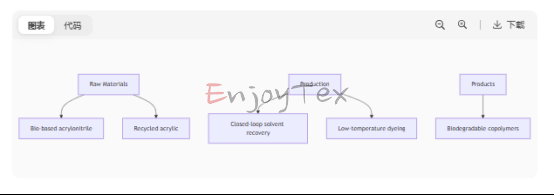

(2) Eco-Upgrades

---

---

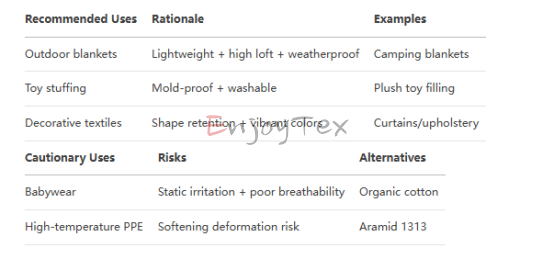

7. Application Guidelines

---

---

8. Market Data Reference

- Cost Comparison:

- Acrylic yarn: ¥25-35/kg

- Australian wool: ¥80-120/kg

- Product Lifespan:

- Home textiles: 5-8 years (Wool: 3-5 years)

9. Future Trends

- Biosynthesis:

Glucose-fermented acrylonitrile (Cargill technology)

- Smart Response:

20% fiber diameter expansion at RH>65% (humidity regulation)

- Nanocomposites:

Graphene coating for electrothermal heating (winter apparel)

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China