Blog

Scratch-Resistant Fabric

Scratch-Resistant Fabric

1. Basic Concept

Scratch-resistant fabrics are functional textiles treated with special materials or processes to withstand daily friction, scratches, and abrasion. These fabrics maintain aesthetic appeal while extending furniture lifespan.

2. Core Technologies

(1) Physical Reinforcement

- High-density weaving: Uses 600D+ high-count yarns (e.g., Cordura® nylon)

- Blend processing: Incorporates Kevlar or carbon fibers

- Surface treatment: Nano-ceramic coatings (Mohs hardness up to 6)

(2) Chemical Modification

- Polyurethane reinforcement: Shore hardness 85A-95A

- Elastomer composites: 300% elongation with full recovery

- Self-healing coatings: Repairs minor scratches at 60°C+

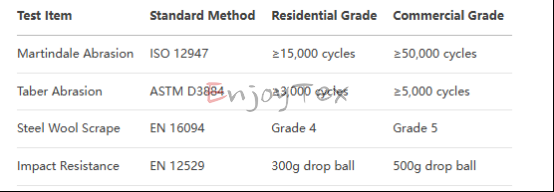

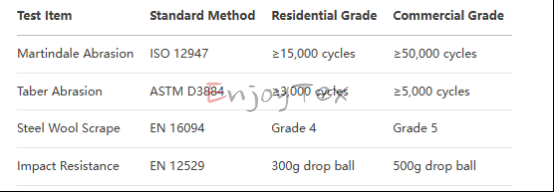

3. Key Performance Indicators

4. Primary Applications

(1) Residential

- Sofas: High-friction areas (armrests/backs)

- Dining chairs: Seats and backs

- Pet furniture: Scratch-prone zones

(2) Commercial Spaces

- Hotel lobbies

- Restaurant booths

- Office seating

(3) Special Environments

- Medical waiting areas

- Airport lounges

- Public transit seats

5. Selection Guide

(1) Residential Options

- Budget: PU-coated polyester (¥200-400/m)

- Mid-range: Kevlar blends (¥500-800/m)

- Premium: Self-healing fabrics (¥1000+/m)

(2) Commercial Requirements

- Must meet CAL 117 flame retardancy

- Recommend ≥50,000 abrasion cycles

- Prefer easy-clean coated finishes

6. Maintenance

- Routine cleaning: pH-neutral cleaners

- Periodic care: Quarterly protective treatments

- Deep cleaning: Annual professional service

- Avoid: Direct sharp object contact, strong acids/alkalis

7. Emerging Technologies

- Graphene-enhanced fibers

- Photocatalytic self-cleaning coatings

- Temperature-responsive self-repair materials

- Bio-based wear-resistant coatings

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China