Blog

Ultra-Fine Fiber Synthetic Leather

Ultra-Fine Fiber Synthetic Leather

1. Core Definition

Ultra-fine fiber synthetic leather is a high-simulation artificial leather manufactured by processing 0.001-0.01mm diameter (1-10 denier) ultra-fine fibers into a three-dimensional network structure,

achieving 80-90% microscopic structural similarity to genuine leather.

2. Microstructural Characteristics

- Fiber Specifications: 0.0008 denier (~1/100 hair thickness)

- Pore Structure: 3D interconnected channels (5-50μm pore size)

- Density: 0.3-0.5g/cm³ (comparable to genuine leather)

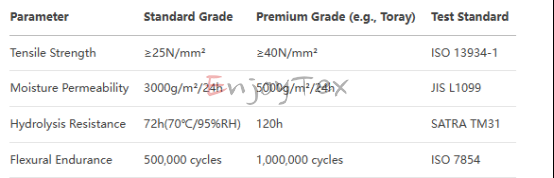

3. Key Technical Parameters

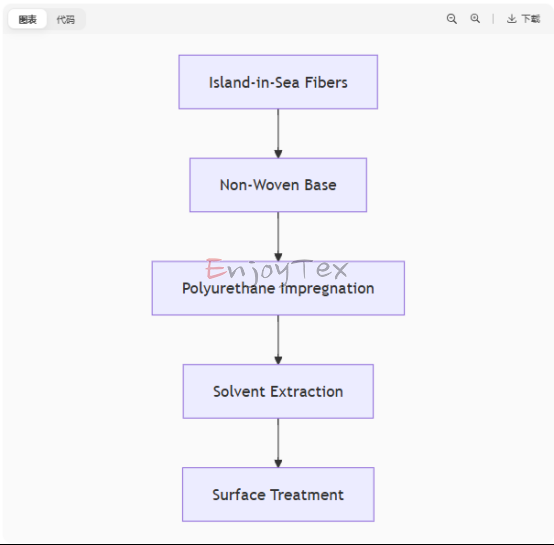

5. Manufacturing Breakthroughs

1. Fixed-Island Technology: 37×37 islands/cm² (vs 16×16 in conventional)

2. Eco-Process: DMF recovery rate >99.5% (EU BAT standard)

3. Functional Composites:

- Graphene thermal conductivity (+20% insulation)

- Nano-silver antibacterial (>99.9% inhibition rate)

6. Application Evolution

- Automotive: Mercedes S-Class seats (0.7mm ultra-fiber, VDA270 odor test)

- Footwear: Nike Flyknit technology (30% weight reduction)

- Medical: Sterilizable surgical drapes (ISO 13485 certified)

- Smart Wearables: Integrated flexible pressure sensors

7. Environmental Advantages

- Carbon Footprint: 8.2kg CO₂/m² (1/3 of bovine leather)

- Materials: 30% recycled PET flakes

- Biodegradability: PLA-based variants achieve >60% degradation in 180 days

8. Market Landscape

![]()

9. Purchasing Guide

- Quality Standards:

- Fiber fineness ≤0.003 denier

- No plastic-like surface feel

- 3D fibrous backing structure

- Red Flags:

- Products priced <¥50/meter are usually PU imitations

- Always request SGS hexavalent chromium test reports (<3ppm)

10. Technology Frontiers

- 4D Ultra-Fiber: Temperature-responsive shape memory (Toray 2024)

- Bio-Fiber: Bacterial cellulose base (+200% strength)

- Digital Ultra-Fiber: 3D-printed textures (0.01mm precision)

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China