Blog

PVC LEATHER

PVC Leather Technical Specifications

1. Core Definition

PVC leather is a polymer-based synthetic material primarily composed of polyvinyl chloride resin, formed through calendering or coating processes on a fabric base (typically knitted or non-woven).

As the earliest commercial artificial leather (introduced in the 1930s), it still holds 38% of the global synthetic leather market (2023 data).

2. Structural Characteristics

- Sandwich Structure:

- Surface treatment layer (0.02-0.05mm, with UV stabilizers)

- PVC foam layer (0.3-1.2mm, containing plasticizers DOP/DINP)

- Base fabric (common 150-300g/m² polyester substrate)

- Physical Parameters:

- Hardness: 60-90 Shore A (adjustable)

- Tensile strength: ≥10MPa (ASTM D638)

- Low-temperature flex resistance (-20℃): ≥10,000 cycles (SATRA PM60)

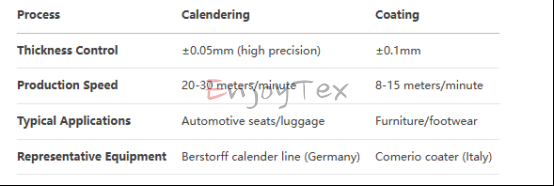

3. Production Process Comparison

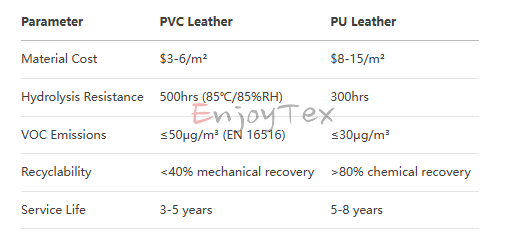

4. Performance Comparison with PU Leather

5. Innovative Modification Technologies

1. Plasticizer-Free Formulations:

- Uses ESO (epoxidized soybean oil) instead of phthalate plasticizers

- Complies with REACH Annex XVII (DEHP <0.1%)

2. Breathability Enhancement:

- Microcellular foaming technology (50-100μm pore size)

- Breathability increased to 1.8mg/cm²/h (vs 0.5 for standard PVC)

3. Surface Functionalization:

- Nano-titanium dioxide self-cleaning coating (photocatalytic decomposition)

- Silver ion antibacterial treatment (>99% antibacterial rate, ISO 20743)

6. Typical Applications

- Automotive: Nissan Sylphy seat covers (0.8mm calendered PVC)

- Medical: Sterilizable protective mats (ISO 10993-5 certified)

- Furniture: IKEA KLIPPAN sofa (750g/m² knitted-base PVC)

- Outdoor Gear: Waterproof tent flooring (2000mmH₂O hydrostatic pressure)

7. Environmental Concerns & Solutions

- Plasticizer Migration:

- Issue: Traditional DOP plasticizers may leach

- Solution: Eco-friendly plasticizers like ATBC (acetyl tributyl citrate)

- Recycling Challenges:

- Current status: <15% global recycling rate

- Breakthrough: BASF's chemical recycling technology enables PVC depolymerization

8. Purchasing Guidelines

thickness = "0.7-1.2mm (for furniture)"

certification = "Require REACH/SVHC reports"

smell_test = "New PVC should have mild plastic odor (pungent odor = inferior)"

return "Professional Selection Guide"

9. Market Trends

- Chinese Manufacturing: Wenzhou/Foshan production zones account for 52% of global output

- Price Trend: Q2 2024 average price ¥18.5/meter (+7% YoY)

- Substitution Threat: TPU materials gaining 12% annual penetration in premium segments

RELATED NEWS

- 2025 Intertextile SHANGHAI HOME TEXTILE,We are waiting for you 2025-06-18

- VELVET FABRIC 2025-08-11

- CHENILLE FABRIC 2025-08-11

- WOVEN FABRIC 2025-08-07

- SUEDE FABRIC 2025-08-11

CATEGORIES

CONTACT US

Contact: Jennie Feng

Phone: +86 18605718133

E-mail: info@enjoytex.com.cn

Whatsapp:+86 18605718133

Add: A206,10# Xiyuan Road Xihu District,Hangzhou City,310030 China